1

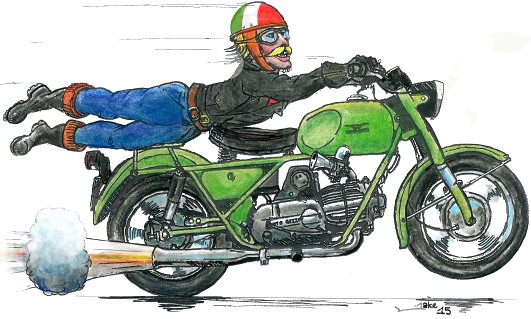

Your other bikes / And now for something completely different

« on: January 16, 2015, 05:09:09 pm »

It's a French Alcyon, so small you could almost carry it on the back of the mighty NF as a"spare".

>

>This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Daft question; you can't change the final drive ratio with a different bevel box?Yes, I thought that as well. However it seems the the rear bevel was common right across the range including the V35 as well. Makes sense I suppose when you think about it, two small spur gears are going to be cheaper to produce that a crown and pinion. Easily fitted during the first assembly of the machine as required. On the V50's the input (Main) gear box shaft is not in line with the engine, hence the need for the two small gears. that make it an easy and cheep place for the Manufactures to change the ratio as they see fit. MG probably never thought anyone would want to change them, and even if they did, they didn't worry about it .